What is a Hydraulic Motor? How Buyers Should Ensure ROI before Investing in One

In a number of machines in industrial set ups, hydraulic motors play a very important role. They are used in construction machines, manufacturing equipment, with drills, cranes and many more machines. If you are deciding to invest in hydraulic pump motors for your industrial application, it is very important to understand how they operate, what their types are, their benefits and the factors you should keep in mind before buying them so that you maximise your ROI.

In the current blog, we will try and break down everything you wanted to know about hydraulic motors.

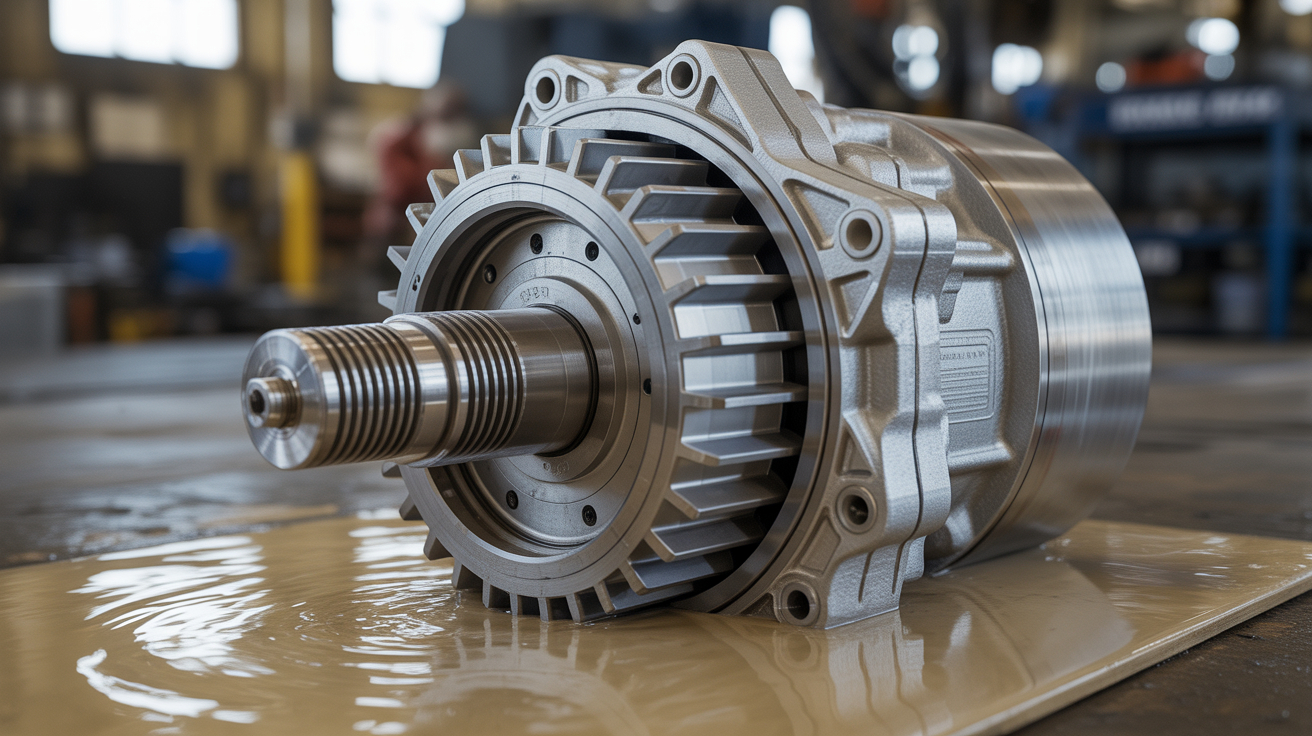

What is a Hydraulic Motor?

In many industrial applications, the hydraulic energy gets converted to mechanical energy for driving speed and torque. It is done with the help of a small but important equipment- Hydraulic Motor. It takes fluid from the pump and transfers it to mechanical energy that is used in tasks like driving wheels, conveyor belts and more equipment.

Since these motors depend on fluid power, they are ideal for working with heavy loads, difficult industrial environments and tasks that need accurate results. They are used by a large number of industries because of their compact size and flexibility.

The Working of Hydraulic Motors

A Hydraulic motor works on a simple principle:

- Hydraulic gear motors have inlet ports through which the fluid enters (under extreme pressure).

- The fluid that enters puts pressure against the internal components causes them to move.

- With the rotation of the internal assembly, the rotational movement gets transferred to the shaft.

- The next step involves driving the load on the machine wrestling in controlled speed and torque.

Types of Hydraulic Motors & Their Strengths

Based on their motor power, Hydraulic Motors come in various designs, each one of them appropriate for their specific needs. Let us break that down and look at some of the types of hydraulic moors:

1. Gear Motors (Hydraulic gear motor)

- Best for: Tasks with heavy-duty applications

- How they work: The force of hydraulic fluid pushes the gear to rotate.

- Benefits: They are simple to operate.

- Limitations: They are not as efficient as other types of gears.

2. Vane Motors

- Best for: Tasks with smooth and medium torque requirements.

- How they work: Vanes are pushed by the fluid for optimum rotation.

- Benefits: They do not make any noise while operating.

- Limitations: They are not appropriate to be used in dusty environments.

3. Piston Motors

- Best for: Excellent for applications involving high-pressure and high-torque.

- How they work: The pistons force the shaft with the fluid movement.

- Benefits: They are of excellent efficiency and great for handling tough loads.

- Limitations: They are more expensive and complex to operate.

Tip: Only use a clear fluid with piston pumps; thus avoiding any damage to the motor and your machine.

Best Hydraulic Motor Suppliers like NTH prioritise your requirements and offer you hydraulic motors that are appropriate for your applications.

Key Advantages of Hydraulic Motors

Hydraulic gear motors are the most important piece of equipment in various industrial systems. Here are some of their advantages.

1. High Torque Output

These motors deliver excellent torque- even when working at low speeds. This makes them ideal for lifting, rotating, and moving heavy industrial loads.

2. Compact but Powerful

Hydraulic motors are small yet are very powerful, making them ideal for limited spaces.

3. Reliable Under Harsh Conditions

Hydraulic pump motors work well even under extensive working conditions and can also handle dust, heat, moisture etc with ease.

4. Variable Speed Control

Their speed can be adjusted and the basis of requirement by the operator.

5. Long Service Life

When properly maintained, hydraulic motors can function for a long time; thus reducing any additional cost.

Where Are Hydraulic These Motors Used?

Hydraulic motors power a wide range of machines across industries:

- Construction Industry

- Agriculture Industry

- Industrial Manufacturing

- Everyday tasks like pallet trucks

Hydraulic motor uses are not restricted to only these. They cover a wide range of other applications manufacturing, aerospace, defense etc.

How to Choose the Right Hydraulic Motor?

When purchasing an industrial hydraulic motor, you should move beyond the hydraulic motor factor. Considering long term use is equally important.

-

Appropriate flow requirement – For industry specific demands, look for motors with required speed and torque. Defines Defines output speed and torque.

- Pressure Ratings – Always look for motors whose pressure is more than your machine’s maximum pressure.

- Mounting Compatibility – Ensure that the motor size is compatible with your machine

- Fluid Type & Seals – Only use the seals that are compatible with the type of oil you use and the operating temperature of your work/environment.

- Environment Conditions – If your set up is in a dusty or a wet place, look for rugged motor options. Some motors are manufactured keeping these specific conditions in mind.

Following the above pointers will definitely give you an edge in terms of reduced downtime, lesser modifications and better ROI.

Hydraulic Motor Reference Table For Buyers

Here is a table about various motor types and comparison between their features.

|

Feature / Spec |

Gear Motor |

Vane Motor |

Piston Motor |

|

Noise Level |

Higher |

Moderate |

Lower |

|

Ease of Maintenance |

Easy |

Moderate |

Requires expertise |

|

Best Speed Range |

Mid to High |

Medium |

Wide range |

|

Starting Torque |

Medium |

Medium-High |

Very High |

|

Fluid Cleanliness Requirement |

Low |

Medium |

High |

|

Long-term Efficiency |

Mid |

High |

Very High |

|

Cost (Initial Investment) |

Low |

Medium |

High |

** these are generic motor performances (based on the motor types)

Ready to Buy?

Hydraulic motors are the most dependable piece of equipment used by various manufacturing, construction and aerospace and various other industries. Therefore, they should be chosen very wisely. Check for their sturdiness, versatility and other important features as mentioned in the blog before you buy them. Any investment should result in excellent ROI. Sourcing your motors from a trusted source is another… but one of the biggest factors to always remember. Collaborating with us- NTH Hydraulics- leading Hydraulic Motor Manufacturer in India had given many businesses exactly what they were looking for and have given us- satisfied customers.