Complete Guide to Hydraulic Hose Pipes for Industrial & Bulk Buyers

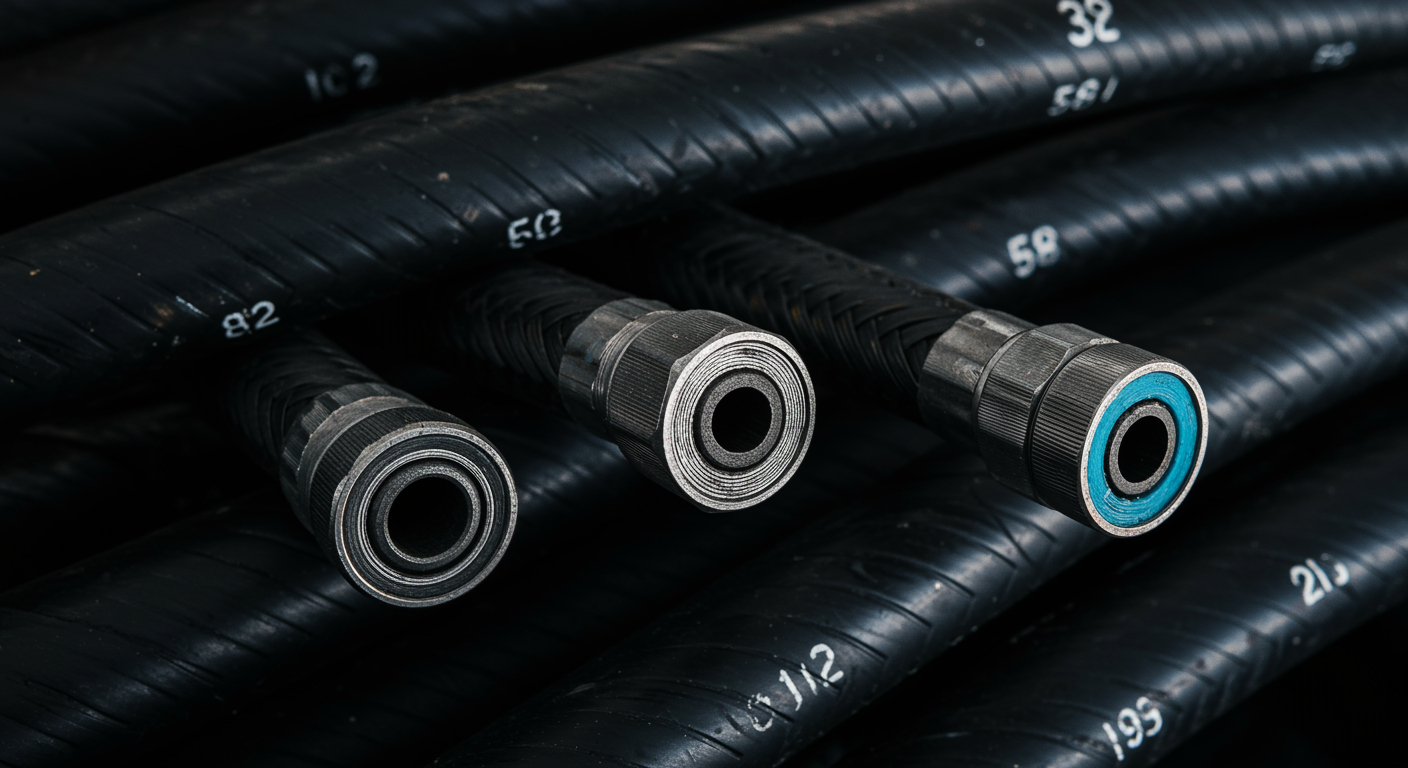

Hydraulic Hose Pipes are flexible high-pressure tubing systems that help to circulate the hydraulic fluid inside the pumps, valves or cylinders. These hoses are specially designed for handling the high-pressure and high-temperature fluid. The primary work of these hoses is transferring the Hydraulic Power Pack from one place to another place without any leakage or performance loss. By this flexible nature it is easily installed in complex machine layouts.

Key Components Of Hydraulic Hose Pipes:-

- Tube: Inner layer in which fluid is flowing, which is made of oil, chemical or heat-resistant material.

- Reinforcement: Steel wire braid or spiral layers, which provide strength to maintain high pressure.

- Cover: Outer protective layer which protects fluid from weather, heat and chemicals.

Types of Hydraulic Hoses

High-Pressure Hoses

- This is specially designed for Heavy-duty machinery

- It is used in excavators, loaders, cranes and mining equipment

- It can handle the load of High working pressure and extreme shock

- It use spiral steel reinforcement (4-wire / 6-wire)

Low-Pressure Hoses

- It is mainly used in return lines, lubrication lines and fuel lines

- Due to low pressure, its design is lightweight.

- It is flexible, easy to install and cost-effective

Thermoplastic Hoses

- It is lightweight and more flexible compared to rubber hoses

- Due to high chemical resistance, it is ideal for chemical plants

- Non-conductive options available—electrical environments are safe

- Low-temperature performance better than rubber hoses

Difference Between 1-Wire, 2-Wire, 4-Wire, and 6-Wire

Why Use Hydraulic Hoses Instead of Steel Pipes?

- Steel pipes are rigid in nature and hoses are flexible and can easily bend

- Lightweight, fast installation and maintenance-friendly

- They absorb vibration, which prevents risk of leakage

- Tight space and complex routing make hoses best option

- Cost-effective and safer compared to steel pipes

How to Choose the Best Hydraulic Hoses for a Bulk Purchase?

Bulk procurement hydraulics is more than just a large quantity hose purchase; It is about maintaining machine uptime, ensuring operational safety, and saving money in the long run. A play of OEMs, distributors, construction firms, and industrial buyers is the selection of the right hydraulic hose supplies.

1. Makes System Safer and Less Prone to Breakdowns

The use of an incorrect hose (wrong pressure rating, wrong fluid compatibility, low-quality fittings) can lead to an increased possibility of:

- Hose rupture

- Oil leakage

- Shutdown of the machine

- Safety risks for the operator

High-quality, appropriately rated hoses are the ones that keep these kinds of failures away in high-pressure systems such as excavators, loaders, presses, and injection machines.

2. Reduces Maintenance Expenditure Over Time

Inexpensive hoses usually have a short lifespan. When buying in bulk, a slight quality decrease can lead to a significant loss.

- Proper hose selection results in:

- Extended product life

- Less frequent hose replacements

- Lower labor costs

- Better performance under heavy-duty cycles

3. Provides Compatibility with All Equipment

An effective procurement plan ensures that the hoses conform to:

- Pressure standards (1-wire, 2-wire, 4-wire, 6-wire)

- Thread standards (BSP, JIC, ORFS, NPT)

- Temperature range

- Fluid type

This prevents problems such as fitting mismatch, leaking caused by a poor seal, or incorrect routing.

4. Decreases Warehouse Complexity

When you decide on the right hose range from a reputable supplier:

- Stock management becomes less complicated

- You do not have to carry the unnecessary SKUs

- Reordering gets more organized

- Lead times become shorter

Constant product specs = a more efficient supply chain.

Cost vs Quality: How Can Bulk Buyers Save Money Without Sacrificing Safety?

For industries that are dependent on hydraulic systems—manufacturing, construction, mining and agriculture—bulk procurement of hoses and fittings is a tool that can dramatically change both the cost side of the equation and the safety side. The main thing is to find the right place where you can still save money without putting machine uptime and operator safety at risk.

1. Performance Standards Should Be First Priority Besides Price

Bulk buyers usually have price as their first point of comparison; however, true cost-saving measures are ones that lead to the selection of hoses that fulfill the following requirements:

- Accurate pressure rating

- Correct impulse cycles

- Temperature + fluid compatibility

- OEM/SAE/EN standards

- More downtime

- More expensive repairs

- Safety hazards

Make economical purchases by choosing the hoses that meet the technical standards necessary rather than the lowest-priced one.

2. They Should Concentrate on the Total Cost of Ownership Rather Than the Unit Price

Bulk buyers can save more if they take into account the lifetime cost. They just have to ask the following questions.

- How often does the product need to be replaced?

- How much labour will be needed to change the hose?

- What are the financial consequences of an unplanned machine shutdown?

- How much loss is faced during productivity?

A high-quality hose that lasts four times as long is eventually cheaper than a low-quality hose that needs to be replaced twice as often.

3. Why Should You Standardise Your Hose and Fitting Inventory?

The use of several brands and types results in the following negative consequences:

- Higher inventory cost

- Mismatching of replacements

- The risk of incorrect combinations

Bulk buyers can achieve a 15–25% saving by:-

- Implementing a standard hose family (1-wire, 2-wire, 4-wire)

- Using fittings from one manufacturer

- Decreasing SKU complexity

Standardisation is equal to better pricing and fewer failures.

4. Get Your Supplies Directly from Manufacturers, Not from middlemen

Direct bulk procurement from a Hydraulic Manufacturers like NTHydraulic is the way to ensure:

- More favorable volume-based pricing

- Consistency in quality

- Provision of technical guidance

- Verifiable pressure/impulse testing

- Delivery that is quicker

By this, you decrease the chance of purchasing duplicate or low-quality hoses.

Conclusion

Choosing the right Hydraulic Hose Pipe is a very important step for every bulk buyer so that they can maintain the machine's safety, operation efficiency and long-term cost savings. Correct pressure, fluid compatibility and impulse rating maintain costs and reduce the safety risk. To make your inventory organised with best quality and reliable hoses, you can trust us

Connect today with NT Hydraulics Manufacturers to get the best customised bulk hydraulics solutions.