How to Select the Right Hydraulic Modular Valve?

Hydraulic systems are dependent on fluid flow, pressure, and direction, which are controlled accurately in order to perform efficiently and safely. The core of this control is the hydraulic modular valve, which is a key element of industrial machinery, mobile equipment, and automation. It is very necessary to choose a hydraulic modular valve that is the right one for the system performance, energy use, and reliability in the long run. An engineer can design a system that will respond accurately under varying load conditions if he knows the hydraulic modular valve working principles.

Such a bad decision may result in the loss of pressure, overheating, leakage, or frequent maintenance problems. Having knowledge of the working principle of these valves and the process of assessing them correctly assists in having optimum operations of the system when subjected to strenuous applications. In complex circuits, different hydraulic modular valve types are selected based on control accuracy and response speed.

Understanding Hydraulic Modular Valves

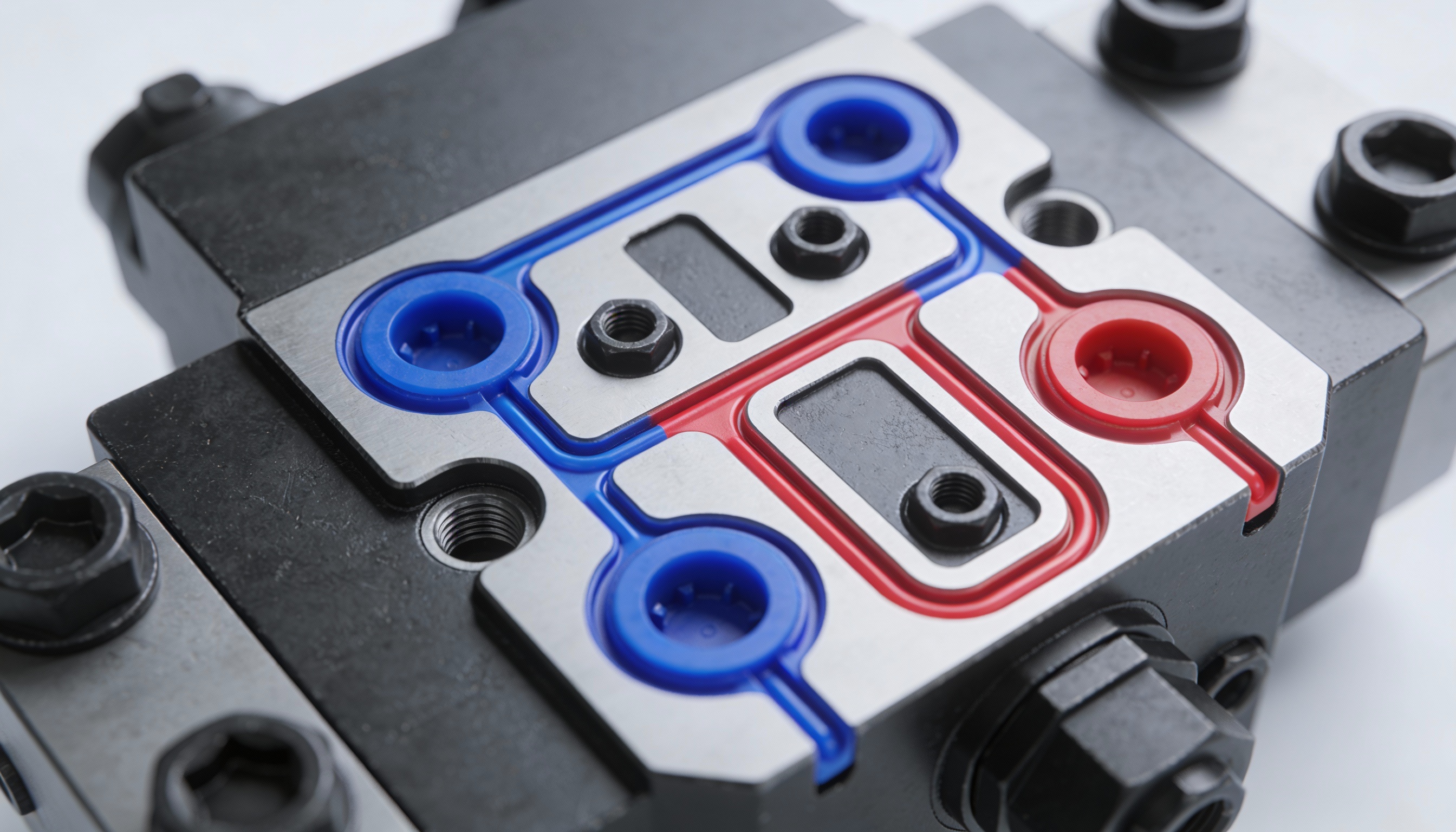

Hydraulic Modular Valves are miniature types of control devices that operate hydraulic fluid in a system to control its direction, pressure, or volume. The modular valves are attached to common subplates or manifolds, unlike traditional piping-based valve setups, where several functions might be stacked on a single subplate, and the valves are commonly stacked. the Modular Valve configuration reduces space usage while maintaining precise hydraulic control.

The design of this module helps to lessen the piping complexity, decrease the number of leaks, and improve the cleanliness as well as the reliability of the system. Moreover, these valves can be found widely in industrial presses, injection molding machines, material handling equipment, machine tools, and power units that require space efficiency and accurate control. Hydraulic modular valve often known as a sandwich valve is often used in stacked systems to add specific control functions without redesigning the circuit.

Why Valve Selection Matters in Hydraulic Systems?

This is achieved by the appropriate selection of the valve to guarantee the smooth running of the system, constant control of pressure, and limit the usage of energy. An incompatible valve may limit the flow, cause excessive pressure drop, or fail to prevent operating conditions. If they are chosen carefully, the response time will be improved, the equipment will become safer, and the pumps, actuators, and seals will be with you for a longer time. Knowledge of hydraulic modular valve working principles ensures better coordination between pumps, actuators, and control elements.

Key Factors to Consider When Selecting a Hydraulic Modular Valve

System Pressure and Flow Requirements

The initial one is to determine the maximum operating pressure and flow rate of the system. The valve chosen has to be rated to deal with such conditions with a good safety margin. Underestimated valves may deform, leak, or fail early, whereas oversized ones can decrease the accuracy and efficiency of control. Different hydraulic modular valve types are rated differently for pressure and flow handling capabilities.

Valve Function and Application Type

Hydraulic modular valves do various functions, including directional control, pressure relief, flow control, and sequence control. It is important to know the exact role that the valve will play on the circuit. There are those systems that need a straightforward on/off control or those that need the accurate regulation of pressure or coordinated movement. A sandwich valve allows these functions to be layered efficiently without increasing system footprint.

Mounting Standards and Compatibility

Modular valves are standardized in designs of mounting like CETOP, NG6, NG10, or NG25. The choice of a valve that is compatible with the existing manifold or subplate would make the installation process easy and compatible with the system. Poor assembly of the mounting can cause leakage or misalignment.

Fluid Type and Operating Environment

They are hydraulic fluid type, range of temperature, and environment. Valves that operate in a high-temperature, dusty, or corrosive environment should be of durable material with the right surface treatment and seals to deliver long-term service.

Types of Hydraulic Modular Valves

Here is a quick comparison table

|

Valve Type |

Primary Function |

Typical Applications |

Key Advantage |

|

Directional Control Valve |

Controls flow direction |

Presses, automation |

Precise movement control |

|

Pressure Relief Valve |

Limits system pressure |

Power units |

Protects components |

|

Flow Control Valve |

Regulates flow rate |

Speed control systems |

Smooth actuator motion |

|

Check Valve |

Allows one-way flow |

Safety circuits |

Prevents backflow |

|

Pressure Reducing Valve |

Maintains lower pressure |

Sensitive equipment |

Energy efficiency |

Each valve is designed for a distinct function, and selecting the right combination is essential for achieving smooth, reliable, and efficient hydraulic system performance.

Advantages of Using Hydraulic Modular Valves

The hydrostatic modular valves have a number of advantages over the traditional piping systems:

- Small size saves on space

- The number of pipe connections is reduced, which reduces the risk of leaks

- Quicker installation and greater system expansion

- Better system purity and availability

- Easy maintenance and troubleshooting

The benefits of modular valves are that they are perfect in a contemporary hydraulic system where efficiency and reliability are key considerations. A modular valve system simplifies future expansion and makes maintenance faster compared to hard-piped assemblies.

Common Mistakes to Avoid During Valve Selection

Most of the problems encountered with systems are a result of improper choice of valves and not component failure. Typical errors are disregarding pressure peaks, neglecting flow specifications, choosing mounting sizes that do not match, or a mismatch of valves that are not appropriate in the working environment. To prevent these mistakes, one needs to analyze the system thoroughly and to seek advice from technical specifications or suppliers with experience.

Best Practices for Long-Term Performance

To provide a long service life and ensure uniformity in performance:

- Pressure and flow ratings should always be checked

- Clean hydraulic oil and filtration should be used

- Make sure they have proper installation torque and alignment

- Conduct regular leakage or wear inspections

- Change seals and damaged parts

The practices will enhance the reliability of the system and minimize unwanted downtimes.

Applications Across Industries

Hydraulic modular valves are popular in the manufacturing industry, construction equipment, agriculture, power generation, material handling systems, and industrial automation. Their flexibility and accuracy ensure they have the use of both high-performance and precise hydraulic applications.

Making the Right Choice for Reliable Hydraulic Performance With NTH

NTH offers first, class hydraulics parts and systems to the customers. For instance, valves, pumps, and other parts that are produced to meet high-performance, long lifespan, and accuracy requirements in both industrial and mobile applications are also supported by reliable service and technical expertise.

The decision to use a hydraulic modular valve is among the most important ones that determine system efficiency, safety, and durability. After a thorough evaluation of pressure ratings, flow requirements, valve functions, mounting standards, and operating conditions, customers are in a position to design hydraulic systems that are strong under heavy work. The correct valve selection thereby becomes a powerful tool for operational efficiency and also cuts down the maintenance cost while extending the lifespan of the entire hydraulic system.